Our Services

Supply and Installation Services:

Manufacturing Services:

Installation Services:

Review and Testing:

Pre-project delivery review services

Quality Control

Consultations Services:

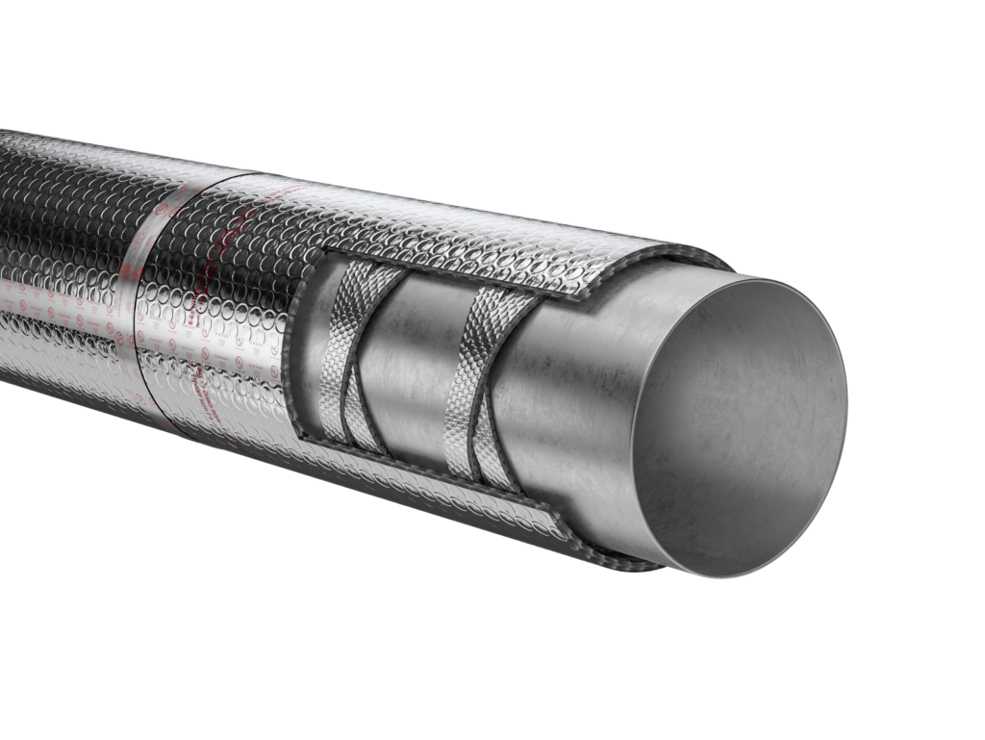

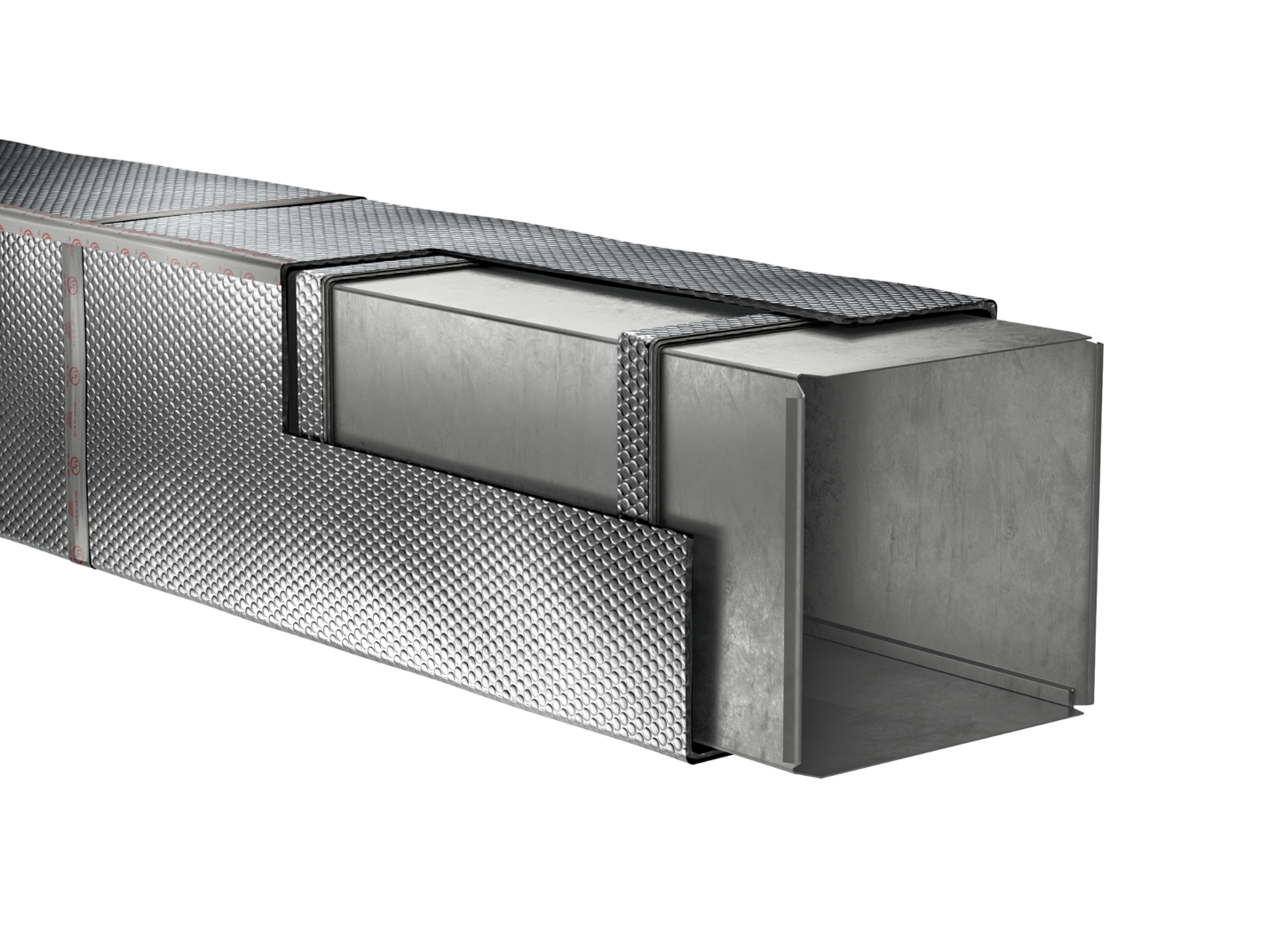

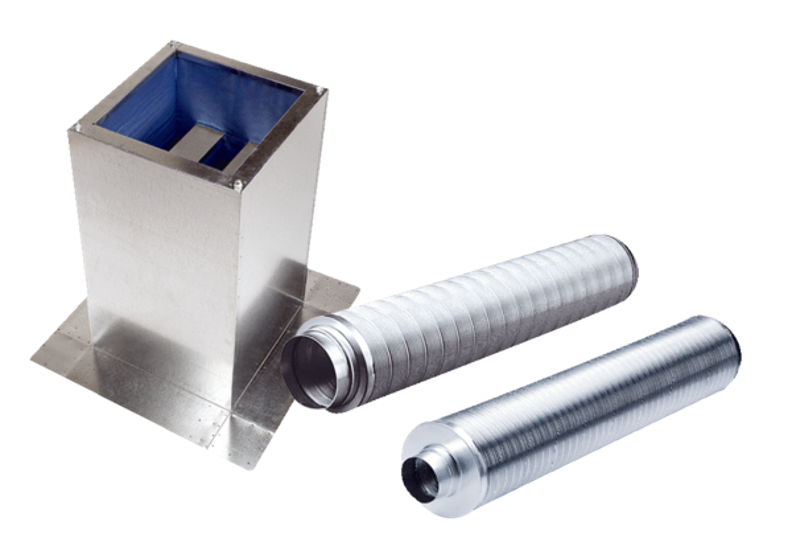

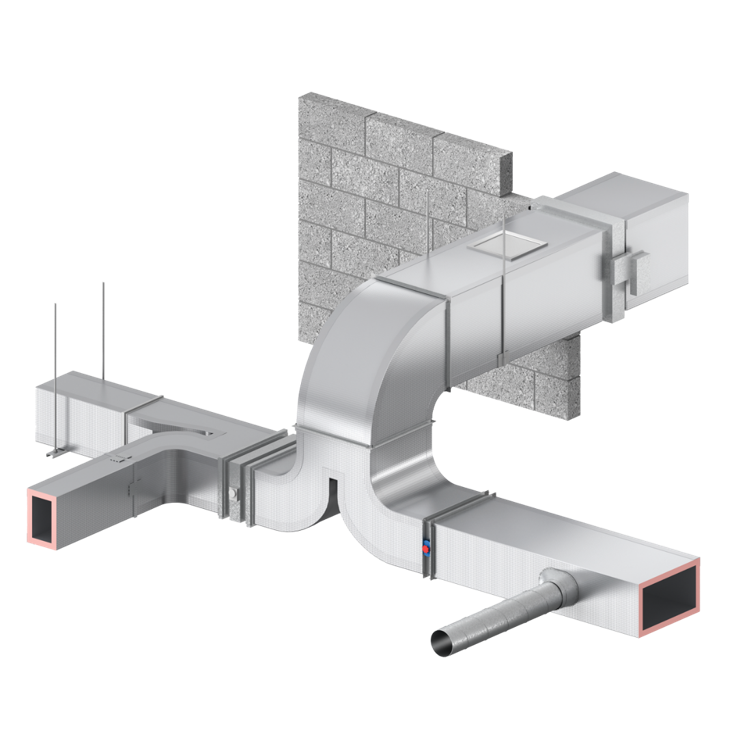

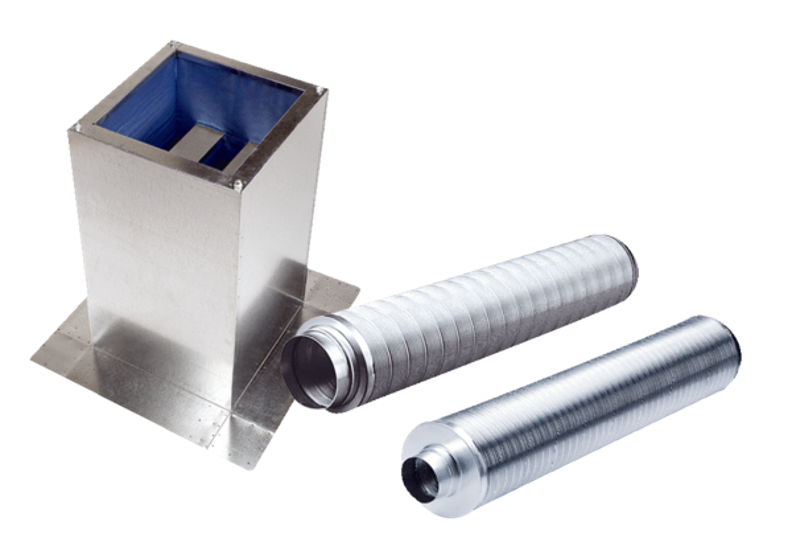

At Madar Al-Qutbain, a premier air conditioning service company, we operate a fully-integrated factory that adheres to international standards for manufacturing air ducts and accessories. Our factory is among the most advanced in Saudi Arabia, with a monthly production capacity exceeding 20 tons. We use high-quality sheet metal from SABIC, with thicknesses ranging from 0.2 cm to 1.5 cm, ensuring products that meet the highest standards and specifications.

At Madar Alqutbain , we operate a fully-integrated factory adhering to international standards and specifications for manufacturing air ducts and their accessories. Our factory is one of the most advanced in Saudi Arabia, with a monthly production capacity of over 20 tons. We use top-quality sheet metal produced by SABIC, ranging from 0.2 cm to 1.5 cm in thickness, meeting high standards and specifications.

We have improved our production lines in collaboration with technical partners to achieve benefits such as:

-

the selection of the best steel types with different thicknesses

-

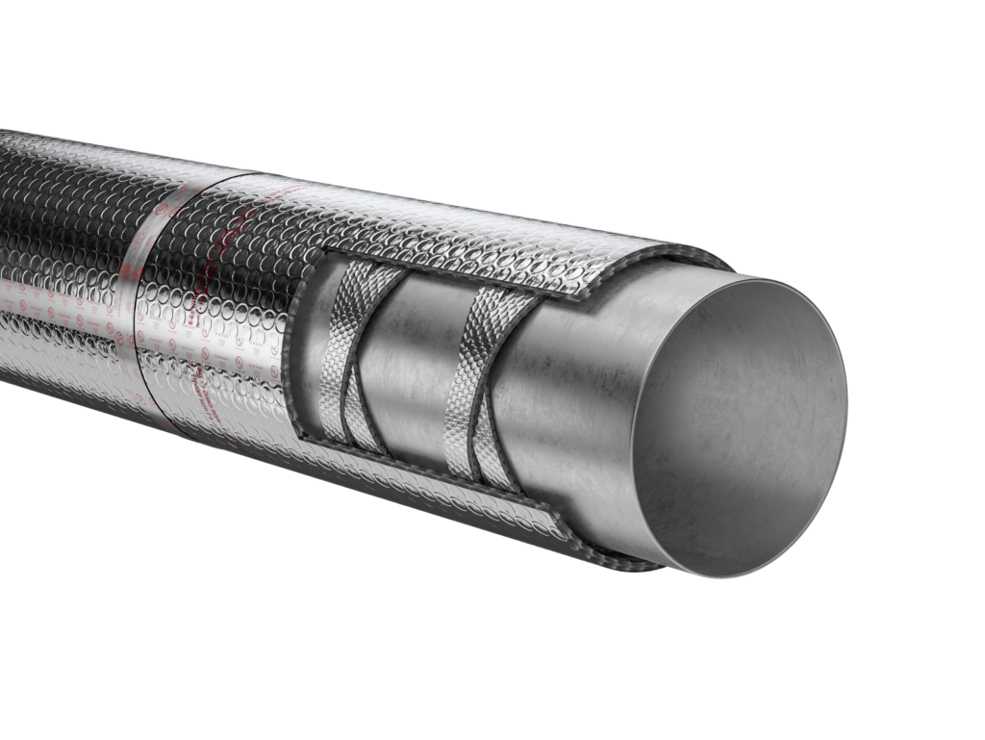

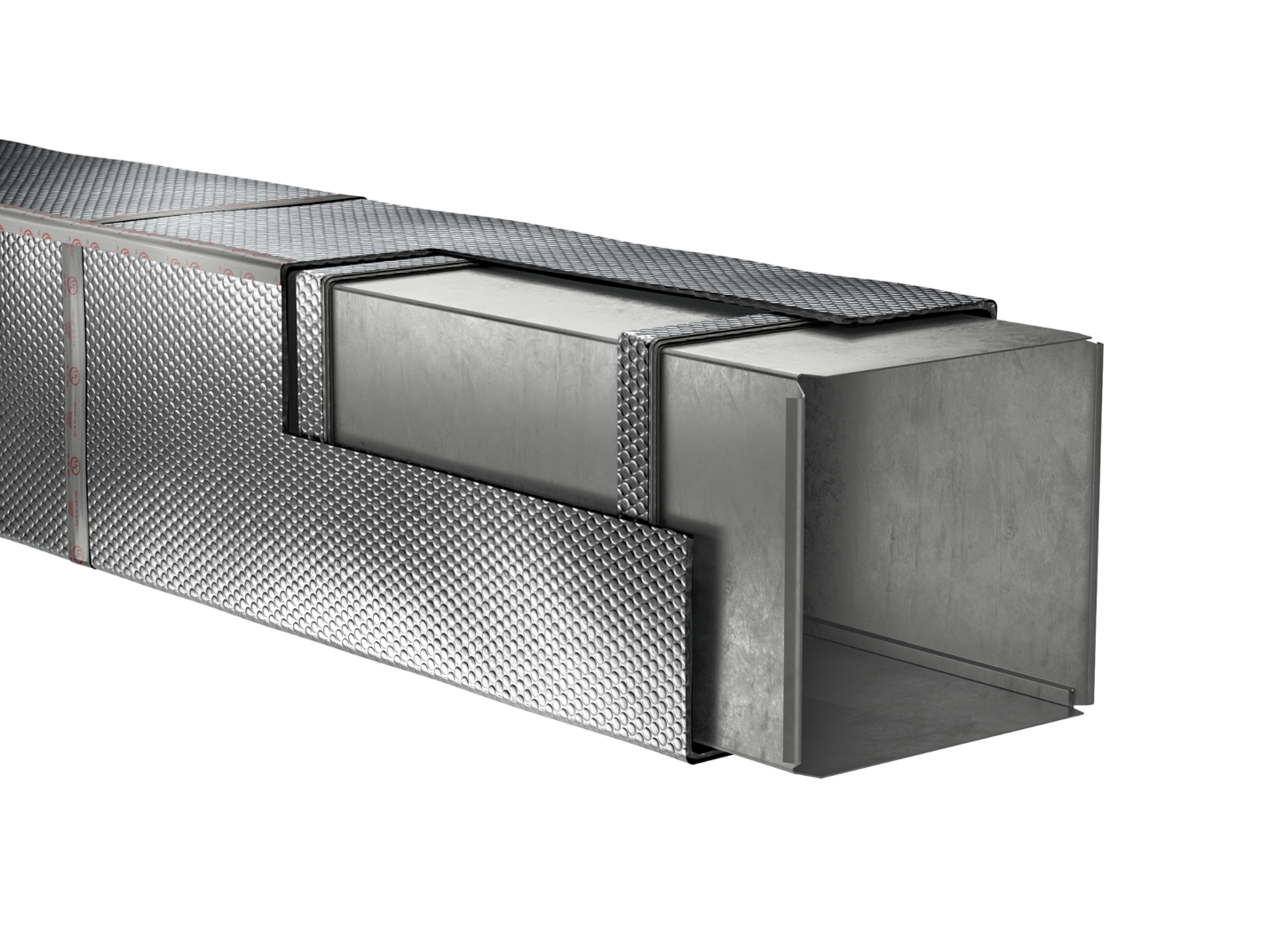

superior duct insulation for leakage and moisture protection

-

excellent sound insulation.

-

The best fabrics for insulation resistant to sun and heat

Installation Services:

-

Review the air duct network according to the approved sheet metal samples.

-

Review the air duct network in terms of sizes according to the execution drawings.

-

Review the air duct network in terms of paths, considering the distances of the decorations and ensuring that no clear air sound is emitted in the room or assembly.

-

Make sure that there is a volume damper or Splitter and Fire damper in the places according to the project execution drawings.

-

Review the Volume damper or Fire damper according to what was approved of these types according to the engineering drawings.

-

Review the Gauge of the sheet metal according to the largest side of the sheet metal as stated in Smacna

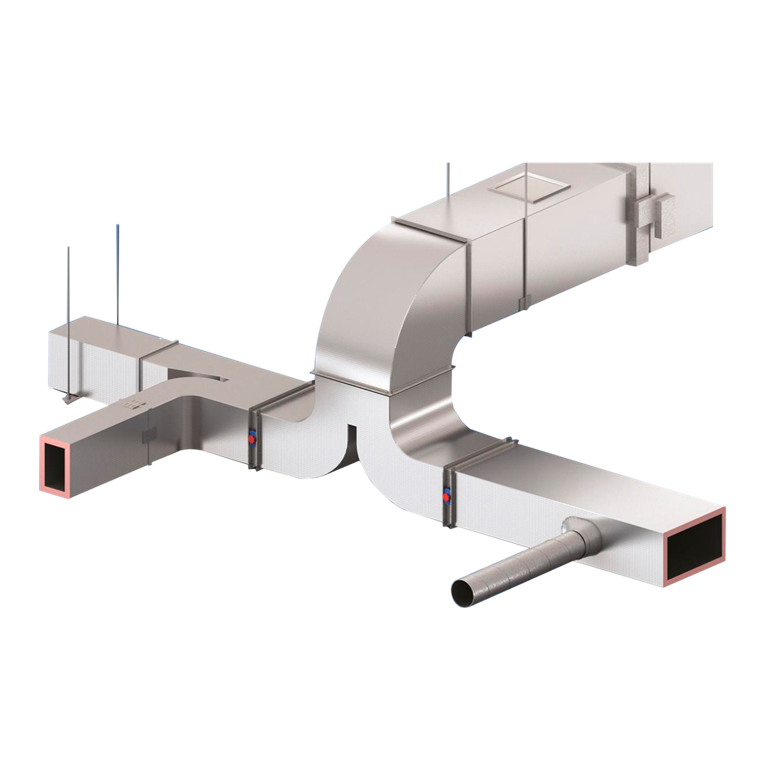

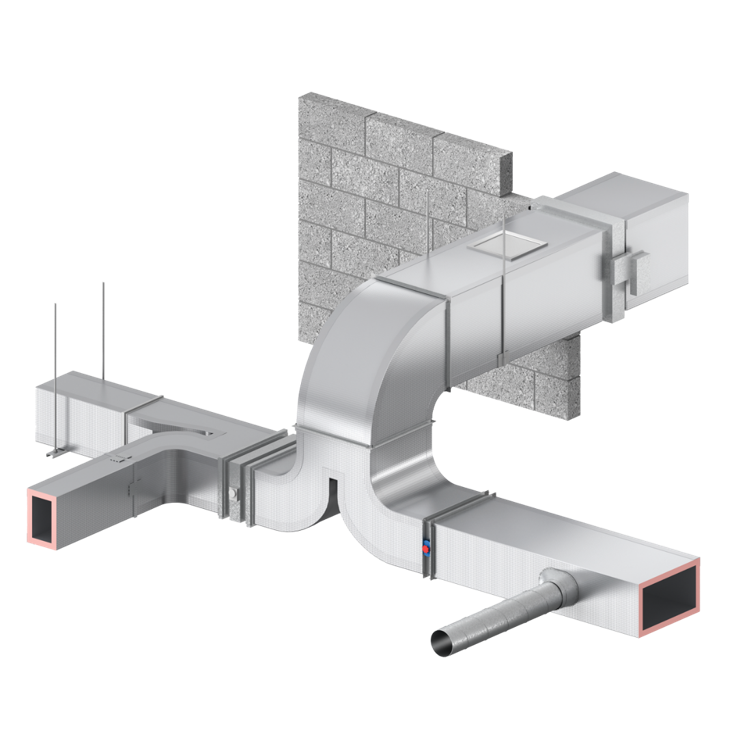

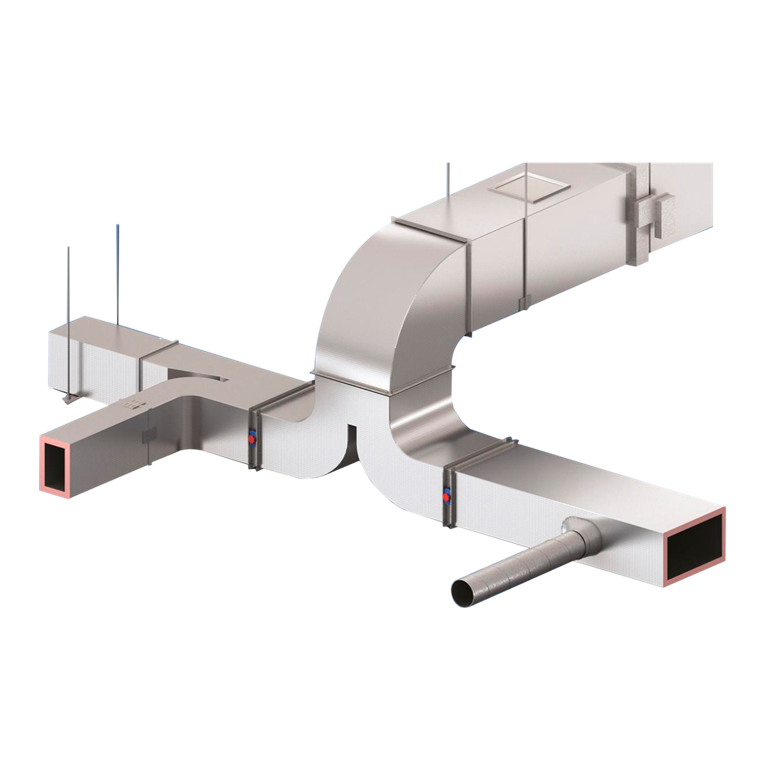

We rely on professionalism in our work by combining manufacturing and installation accuracy by paying attention to the following:

-

Preparing detailed plans with the latest programs according to international engineering standards.

-

Managing the schedule of manufacturing, supply, and installation of air ducts (ducts) effectively.

-

Executing the preparation and manufacturing works under engineering supervision and professional workers and manufacturing machines with high and distinguished capabilities.

-

Installing duct works by specialized technicians and under the supervision of engineers with a high degree of efficiency.

The mechanism of work in installation and testing:

-

Make sure to close the ends of the air ducts according to the method stated in the specifications or Smacna.

-

Make sure that the joints of the air ducts are connected according to Smacna specifications.

-

Make sure that there are Guide Vares at the corners of the air ducts (Turing vanes) so that we maintain the ability of the air to reach properly.

-

Make sure that there is a detection door in the sheet metal before or after the Fire damper.

1 - Before Testing

-

Review the insulation according to the approved insulation samples (internal and external density, as well as thickness).

-

Ensure that large sized air ducts are insulated with staples

-

Emphasis on installing covers when penetrating the wall. And paste aluminum tape at the insulation welds

-

Emphasize the use of anti-condensation paste at the joints of the insulation pieces

-

Reviewing according to the regulations, engineers must be present to receive the project from the engineer implementing the project

2 - After Testing

-

Cover the corners of the air ducts and the ties between the sheet pans with silicone of the same color

-

Insulating cold air ducts and wrapping insulation of air ducts in open spaces to protect them from external weather factors such as humidity and heat and their impact on performance.

-

Review the type, thickness, and dimensions of the load (angle or beam) (smacna page 4,7)

-

Make sure to paint the duct supports

-

Review the load arm according to the specifications (Smacna page 4,6) (Smacna)

-

Review the vibration inhibitors (Canvace) to ensure excellent performance.

-

Make sure that the air ducts do not touch the walls and do not make noises during operation

-

A bird screen and bell mouth must be installed on the air ducts that draw air from the ceiling void, which is a net that protects from rats and insects

-

Make sure to make (Take off) for sheet metal branches and Flexible duct and make sure to connect it with Coller and by Clamp.

-

Review (Plenum) on A.H.U outlet in terms of sizes and presence of Volume Damper on the main branches.

-

Make sure the air outlets are approved by the architect.

-

Air outlet fixing screws must be galvanized or painted with thermal paint.

-

Review the locations of installing the air outlets according to the engineering drawings and review them in terms of guides and control valves and review the sizes of the air outlets.

-

Review plenum box for diffusers and make sure they are insulated with armflex with glass wool.

-

Make sure that the flexible that feeds with cold air is insulated internally and has Coller installed on it and has been tied with climb when connecting it with sheet metal and a Plenum Box

-

Making air conditioning, and cooling plans, and supervising their implementation

-

Providing engineering consultations on the plans before starting approval and implementation

Supply and Installation Services:

We collaborate with global importers and manufacturers of air conditioning and refrigeration systems to provide our customers with a wide range of choices that cater to their specific project needs. Our expert team ensures the highest technical standards in execution.

Manufacturing Services:

At Madar Alqutbain , we operate a fully-integrated factory adhering to international standards and specifications for manufacturing air ducts and their accessories. Our factory is one of the most advanced in Saudi Arabia, with a monthly production capacity of over 20 tons. We use top-quality sheet metal produced by SABIC, ranging from 0.2 cm to 1.5 cm in thickness, meeting high standards and specifications.

We have improved our production lines in collaboration with technical partners to achieve benefits such as:

- the selection of the best steel types with different thicknesses

- superior duct insulation for leakage and moisture protection

- excellent sound insulation.

- The best fabrics for insulation resistant to sun and heat

Installation Services:

Installation Services:

- Review the air duct network according to the approved sheet metal samples.

- Review the air duct network in terms of sizes according to the execution drawings.

- Review the air duct network in terms of paths, considering the distances of the decorations and ensuring that no clear air sound is emitted in the room or assembly.

- Make sure that there is a volume damper or Splitter and Fire damper in the places according to the project execution drawings.

- Review the Volume damper or Fire damper according to what was approved of these types according to the engineering drawings.

- Review the Gauge of the sheet metal according to the largest side of the sheet metal as stated in Smacna

We rely on professionalism in our work by combining manufacturing and installation accuracy by paying attention to the following:

- Preparing detailed plans with the latest programs according to international engineering standards.

- Managing the schedule of manufacturing, supply, and installation of air ducts (ducts) effectively.

- Executing the preparation and manufacturing works under engineering supervision and professional workers and manufacturing machines with high and distinguished capabilities.

- Installing duct works by specialized technicians and under the supervision of engineers with a high degree of efficiency.

Review and Testing:

The mechanism of work in installation and testing:

- Make sure to close the ends of the air ducts according to the method stated in the specifications or Smacna.

- Make sure that the joints of the air ducts are connected according to Smacna specifications.

- Make sure that there are Guide Vares at the corners of the air ducts (Turing vanes) so that we maintain the ability of the air to reach properly.

- Make sure that there is a detection door in the sheet metal before or after the Fire damper.

Pre-project delivery review services

1 - Before Testing

- Review the insulation according to the approved insulation samples (internal and external density, as well as thickness).

- Ensure that large sized air ducts are insulated with staples

- Emphasis on installing covers when penetrating the wall. And paste aluminum tape at the insulation welds

- Emphasize the use of anti-condensation paste at the joints of the insulation pieces

- Reviewing according to the regulations, engineers must be present to receive the project from the engineer implementing the project

2 - After Testing

- Cover the corners of the air ducts and the ties between the sheet pans with silicone of the same color

- Insulating cold air ducts and wrapping insulation of air ducts in open spaces to protect them from external weather factors such as humidity and heat and their impact on performance.

Quality Control

- Review the type, thickness, and dimensions of the load (angle or beam) (smacna page 4,7)

- Make sure to paint the duct supports

- Review the load arm according to the specifications (Smacna page 4,6) (Smacna)

- Review the vibration inhibitors (Canvace) to ensure excellent performance.

- Make sure that the air ducts do not touch the walls and do not make noises during operation

- A bird screen and bell mouth must be installed on the air ducts that draw air from the ceiling void, which is a net that protects from rats and insects

- Make sure to make (Take off) for sheet metal branches and Flexible duct and make sure to connect it with Coller and by Clamp.

- Review (Plenum) on A.H.U outlet in terms of sizes and presence of Volume Damper on the main branches.

Consultations Services:

- Make sure the air outlets are approved by the architect.

- Air outlet fixing screws must be galvanized or painted with thermal paint.

- Review the locations of installing the air outlets according to the engineering drawings and review them in terms of guides and control valves and review the sizes of the air outlets.

- Review plenum box for diffusers and make sure they are insulated with armflex with glass wool.

- Make sure that the flexible that feeds with cold air is insulated internally and has Coller installed on it and has been tied with climb when connecting it with sheet metal and a Plenum Box

- Making air conditioning, and cooling plans, and supervising their implementation

- Providing engineering consultations on the plans before starting approval and implementation